Part 1 -India: A Powerhouse for Castings, Fabrication & Machined Components

- Venkat Raghava

- Jul 16, 2024

- 3 min read

Updated: Aug 20, 2024

In today’s globalized world, companies are constantly searching for reliable and cost-effective manufacturing partners. India has emerged as a frontrunner in this arena.

Recently as part of an assignment to identify new suppliers for Castings, Fabrication, and Machined Components for a US based customer, I got the chance to visit numerous suppliers all over the country. I’ve worked on supplier development & onboarding during my career and have been visiting manufacturing suppliers in India and other countries for close to 20 years. What struck me during my recent visits was how much India’s manufacturing scene has evolved over the past ten years or so. The suppliers I visited included Small & Medium Enterprises, along with some large companies.

In this article, I will delve into some interesting themes that I found to be common across most of these suppliers. This is not to say this holds true for the entire manufacturing industry, but for a cross section of suppliers I visited.

Skilled Workforce:

Every supplier had a rich talent pool of engineers, machinists or foundry workers. This skilled workforce was the driving force behind these companies’ successes. It was encouraging to see many women on the shop floor, whether it was setting the cores in a foundry or operating a special purpose machine in a machine shop. One thing that stood out was how companies were investing in the training and skill development of their workforce. Whether it was a welding simulator for welder qualification or a Dojo training centres for class room & hands on training. (The latter is in part largely driven by the requirement of one the largest Automotive OEMs). Many of the Operations heads were convinced that this investment in people is helping them up the game on the shop floor, whether it is productivity or quality.

Modern Infrastructure:

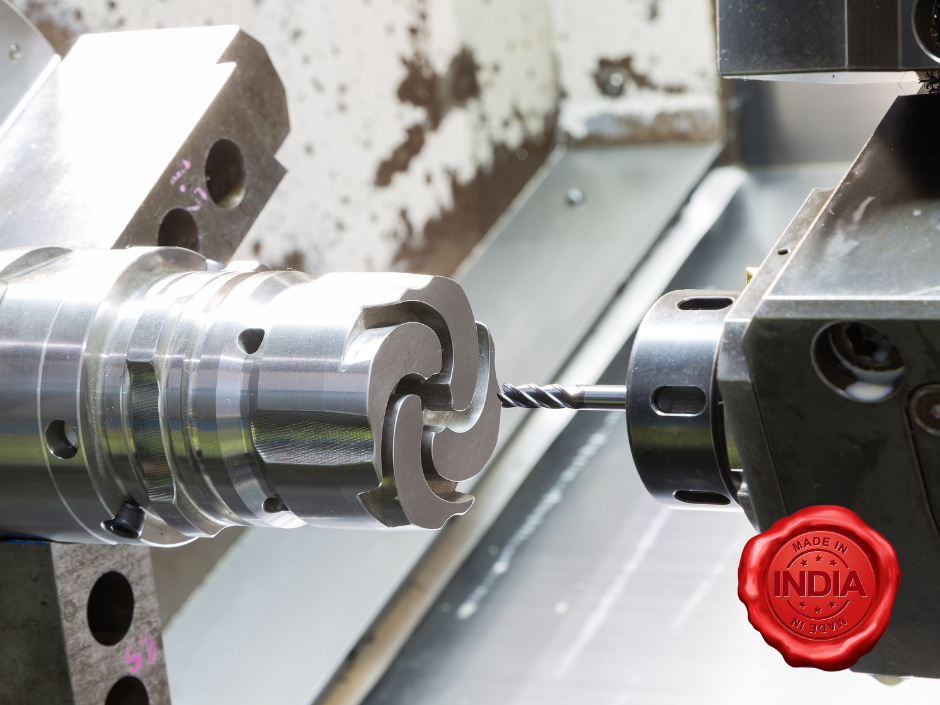

Gone are the days of outdated equipment. Many of these suppliers have increasingly invested in cutting-edge machinery like 5 Axis CNC machines, Turn Mills & advanced casting technologies (lost-foam casting). Almost all fabrication suppliers had advanced Laser or Plasma cutting machines, Robotic Welding and the latest Nesting software. CAD/CAM & Simulation software were used even by the smaller players to ensure tight tolerances; complex designs and optimal material utilization can be realized. Several companies are embracing Industry 4.0 and have integrated their manufacturing facility from incoming parts tracking to finished goods shipment. QR codes were ubiquitous in their presence on the shop floor. One supplier used QR code for getting employee feedback!

Quality Focus:

Many suppliers export parts to USA, Germany and other countries, and they have embraced stringent quality control measures to meet the requirements of these global customers. Welders are qualified as per American Welding Society (AWS) or ISO standards. The foundries follow American Foundry Standards (AFS) or ISO guidelines for their operations. Inspection techniques like CMM and Non-Destructive Testing (Ultrasound Scanning, Radiography, etc) which were earlier being used mostly by the larger companies are being deployed by several of the small to mid-size companies. Like Safety, Quality is always a continuous improvement but it was good to see the quality culture being nourished in these companies.

Sustainability Efforts:

There’s a growing movement towards eco-friendly practices within the Indian manufacturing sector. Many suppliers had installed solar panels on the roof and were getting more that 50% of their electricity requirements from solar and other renewable sources. Foundries have invested in sand reclamation and recycling of scrap was a big part of the casting operations. (which is more for cost). Many of the suppliers are participating in the Government of India initiative of ZED (Zero Defect, Zero Effect) to reduce waste generation, water recycling, use of energy efficient devices, responsible waste disposal and have embraced sustainability as a way of life on the shop floor.

I’ll be writing more in my next article on the areas where I think the suppliers need to improve, which will go a long to boost the confidence of overseas customers.

Comments